RENDERtex

RENDERtex

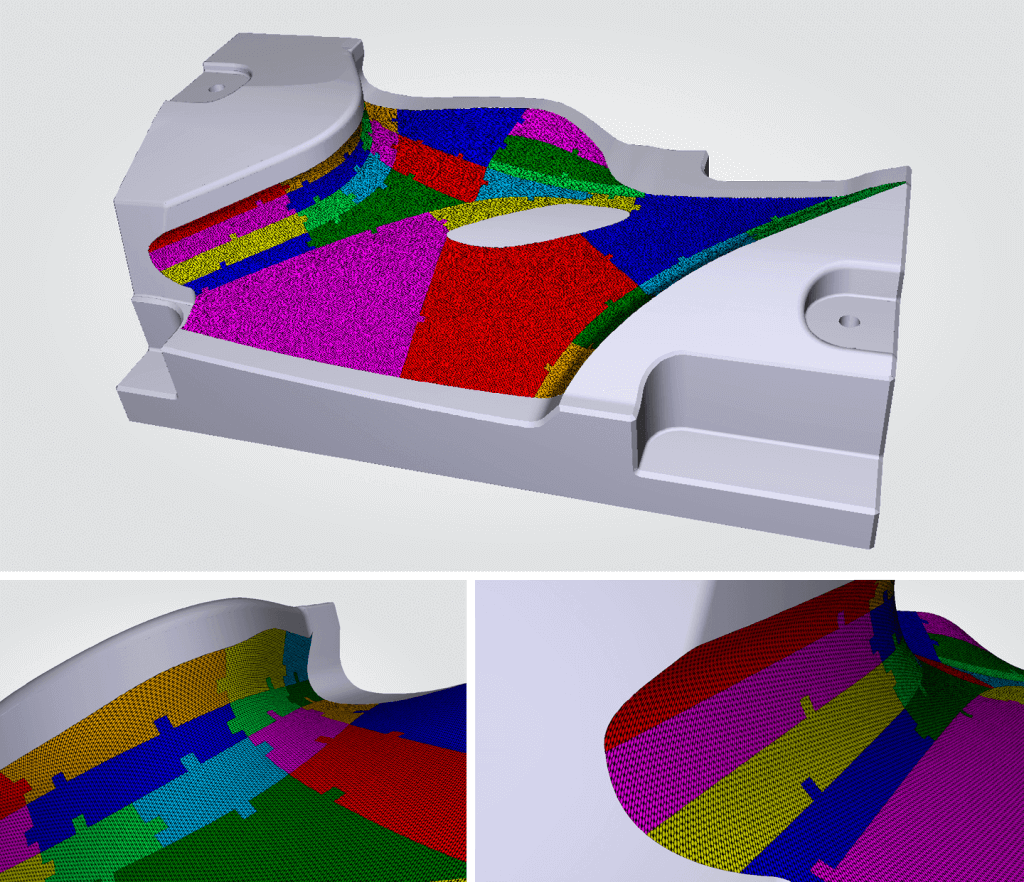

Alternative to the laser engraving process

The same way laser engrave obliges to a pre-mapping of the texture on the CAD file, with RENDERtex we do the mapping first and then unroll that file to produce the films in pieces, to after be mounted on the tool surface and etched on a chemical bath.

This process has the advantage, for geometrical patterns, to assure a more controled distortion, by making use of computational parametric power, as it allows a pre-visualisation of how the pattern will fit on the product/tool, and make adjustments if necessary, before etching it.

The accuracy of the process assures perfect seamless textured surfaces.